MDD : Counterattacks from premium parts manufacturers (2/2)

As private labels anticipate growth and enhancement, significant questions about profitability may emerge for large manufacturers in the aftermarket sector. This industry is already grappling with substantial investments compelled by the mandatory adaptation of their original equipment production for the new electric market. However, premium parts manufacturers have compelling arguments to counter the strategies of distributors embracing private labels and to safeguard their share of the premium market.

While the outlook for virtuous premium parts might be challenging, not all is lost. Particularly for the segment of vehicles up to five years old, where their position remains secure. The imperative to move to electric provides equipment manufacturers with the opportunity to devise innovative solutions and introduce new ranges of components with high added value.

This approach initially serves to justify replacement part prices. Especially at the onset of the electric era, these prices can partially offset the anticipated decline in the frequency of maintenance and repairs.

This hinges, of course, on equipment manufacturers, financially strained by electric investments, avoiding the necessity to halt or divest their after-sales activities. Such a move would result in relinquishing the "electro-premium" value to manufacturers eager to take over distribution—an outcome they are actively preparing for.

Buy better to reduce your prices

For older vehicles, major equipment manufacturers still possess effective strategies to counteract the encroachment of private labels on their premium brands. They achieve this by combining an aggressive price approach with preserved margins.

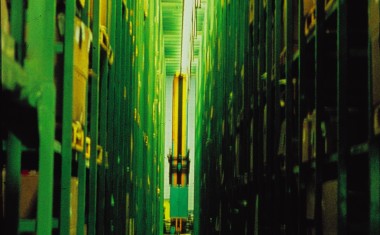

One time-tested method, persistently effective especially in a globalised marketplace, involves strategically sourcing additional products or even core ranges from locations with the lowest production costs. For a premium equipment manufacturer, there's minimal quality risk as they can ensure that their specifications are adhered to by even the most unconventional producers.

This same strategy of intelligently diversified and rigorously validated sourcing guides renowned equipment manufacturers, who may oversee the complete assembly of a comprehensive product range. This approach explains why brake discs, regardless of the equipment manufacturer, are predominantly sourced from China—whether for original equipment or spare parts.

Skilfully adjust the price lever

Opting for strategic procurement, especially when complemented by another effective tactic, empowers those offering extensive and comprehensive spare parts ranges. This involves judiciously reducing prices on the most sought-after and competitive references (where private labels are prevalent) without bearing the full brunt of the impact. Instead, the price cursor is selectively pushed towards other, more exclusive references. By minimising the premium/private label differential on commonly requested, highly competitive references, distributors, repairers, and even DIY enthusiasts are less inclined to switch to unfamiliar products.

Orchestrating a multi-brand positioning

Another viable strategy that can be seamlessly integrated is to position several brands differently, preferably well-established ones. This approach aligns with the perennial "Good-Better-Best" positioning, ensuring comprehensive coverage across the market for one or more ranges of parts.

However, some overzealous equipment manufacturers, overly enamoured with economies of scale and confident in their market dominance, have occasionally veered off course. Believing they could quietly and artificially allocate a single part to all three categories, they underestimated the shrewdness of distributors, garages, and even certain influencers. The repercussions were not only detrimental to their image but also led to repercussions in terms of distributor referencing.

Exploring additional licensing or brand extension strategies

Several alternative strategies exist to enter new markets or counter private labels effectively with minimal risk. Licensing, for instance, enables companies to outsource the production and distribution of branded products. This often involves using reputable brands owned by the equipment manufacturer but no longer actively used. It is akin to range extension or brand stretching, allowing a distinguished manufacturer to apply its established brands to product ranges that extend beyond its core business, typically in the retail sector. Nevertheless, maintaining brand integrity necessitates adherence to closely monitored specifications, contingent on a lucrative licensing contract.

In more unconventional markets where adaptable parts and their unbeatable prices prevail, a few audacious equipment manufacturers opt to lower their specifications, ensuring their brand remains competitive and accessible. However, caution is paramount in such cases. Manufacturers must ensure the market separation is robust to prevent the inadvertent arrival of these branded products to more structured markets, possibly via unconventional channels, that undermine sales.

Retrouvez la version en Français : Les contre-attaques des équipementiers premium